Regarding PCB design, many electronic engineers are very skilled. As a technical developer, the PCB design process is not smooth sailing. For the "siege lions" of different levels (ranks), sometimes they are happy and sometimes sad.

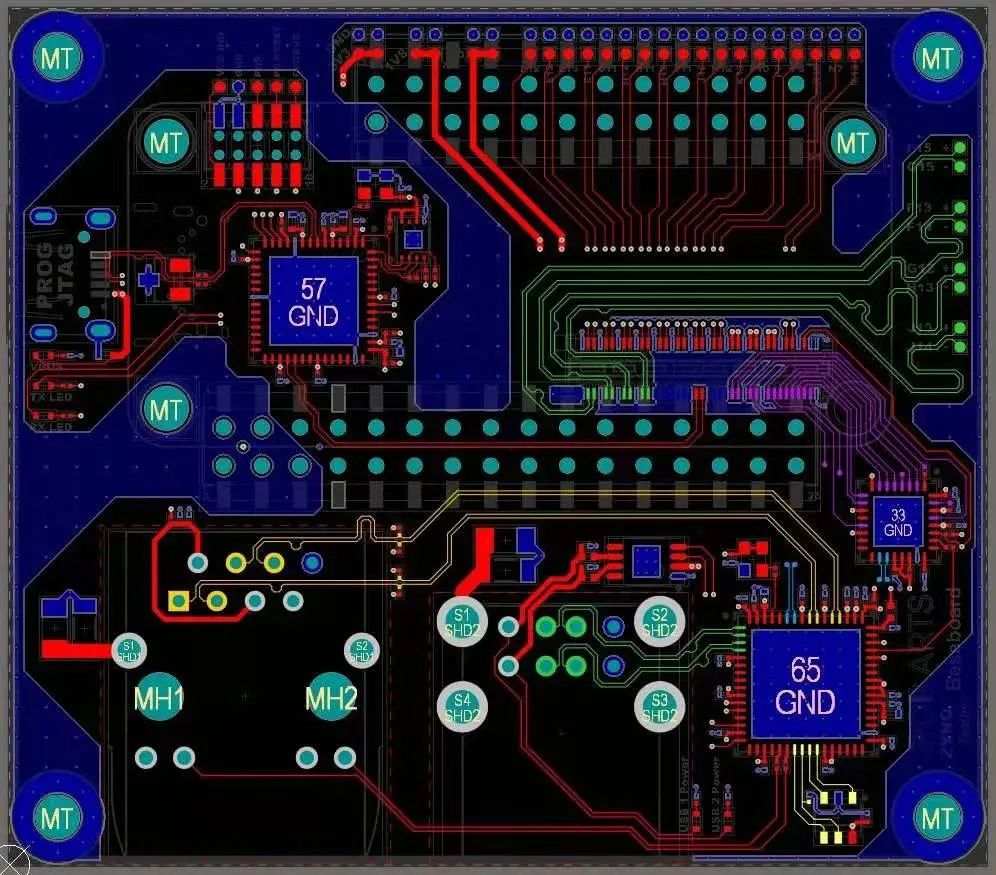

PCB design, from the beginning, I have been exposed to many rules (how much the line width is in miL, how large the Via setting is, how to make screw holes, how to apply copper, etc.). Many are used to it.

So, let's change to a fresh technical topic, PCB design, have you heard of "sour corner"? What is "sour angle"? Sour beans? It doesn't sound very clear. Many engineer friends have a hard time thinking what exactly is it? Today, I would like to talk with you about the sacredness of "Sour Angle".

In the PCB industry, Acid Traps is called "acid angle". First of all, let's translate Acid Traps to understand what it means:

It turns out that the English literal translation is "acid trap", and the keyword "trap" appears here, and everyone immediately thought of stepping on the pit. It is said that failure is the mother of success, and it is difficult to enrich and enrich actual combat experience without stepping on the pit.

The big guy steps on the pits and explores the road more, and the younger brother takes every step in the back, the road of PCB design, and enjoys the sourness of pulling wires on the computer screen. I am determined to pull out the PCB wire around the earth 3 times. The so-called temporary Pulling the line is cool for a while, and pulling the line has been cool all the time, probably that's it!

To know what is sour angle, it is important to understand the PCB production process

Engineers who are familiar with the PCB production process know that before PCB production, the PCB diagram is drawn through the circuit board design software, and then the PCB processing factory's etching process is performed, and finally the designed PCB circuit is etched on the copper clad laminate.

In the basic process of the PCB production process, the most important is the etching process, which uses chemical treatment to remove the unwanted copper on the CCL by etching, and then leaves the required circuit diagram, while Acid Traps can be said to be etching to a certain extent. "side effects".

The chemicals that etch the circuit should be removed in the neutralization and water washing steps, but in the acute angle area formed by the PCB connection, that is, the place where the acute angle is the narrowest, it is easy to cause corrosive chemical residues, and it is like a trap to encircle and suppress the residual corrosive chemicals. substance. By slowly and continuously corroding the copper in the acute angle area, after a long time, the line resistance of the trace will increase or a virtual connection state will occur, and it is easy to short-circuit faults, which is very difficult to troubleshoot. This is the headache of Acid Traps "acid" angle" phenomenon.

PCB trace angle problem

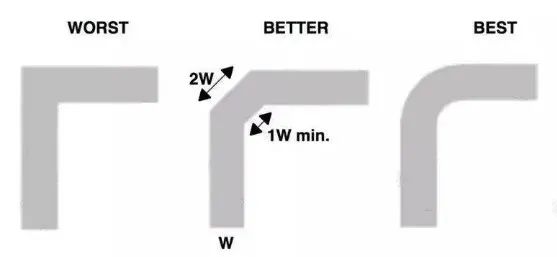

This involves a PCB routing angle issue, which has been emphasized by everyone all the time: Do not go at right angles for routing! So, the question is, don't let the right angle go, is it better to go at a 45° angle, or to go in a circular arc? Is 90° right-angle wiring really okay?

At the beginning, I was very entangled in the corners of the wiring. Check the history of the predecessors. In the 1990s, Intel introduced the PCI bus technology. Since then, it has accelerated the development of the era of "high-speed" systems. As for whether the PCB traces can take an acute angle, the conclusion is definitely not acceptable. From the DFM aspect of the PCB, the acute angle of the PCB trace should be avoided, and it is also possible to avoid stepping on the pit (Acid Traps phenomenon).

How to avoid "sour angle"?

The key point, the practice of avoiding Acid Traps is actually very simple, that is, avoid acute-angle routing. Theoretically, 90° traces will have a slight adsorption effect of corrosive chemicals, so to be safe, try to avoid 90° traces. For the T-shaped intersections of traces, you can add teardrops or repair them with slashes.

More exciting articles welcome to visit to the official website :https://www.cdebyte.com