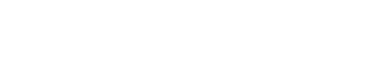

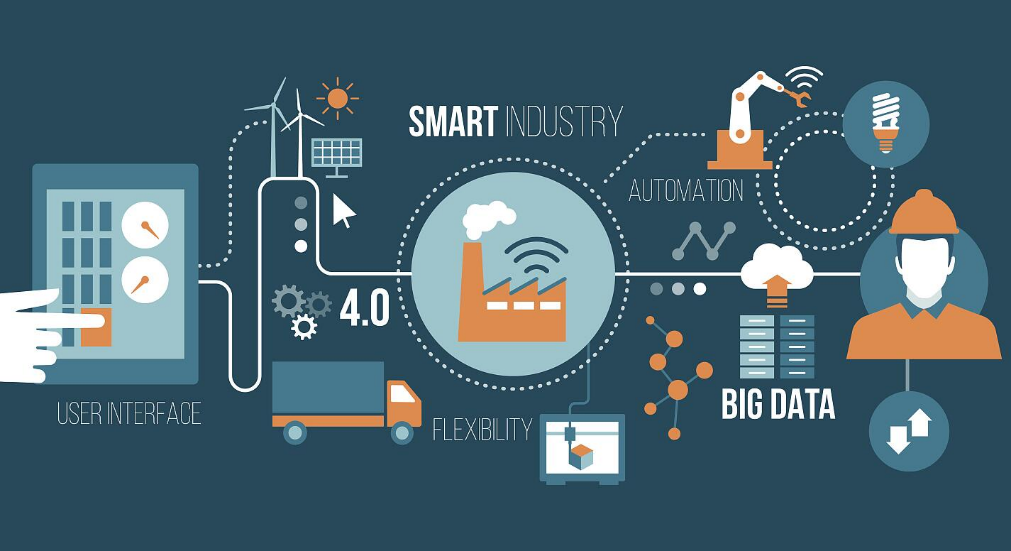

IIoT (Industrial Internet of Things) is the abbreviation of Industrial Internet of Things. It integrates various acquisition and control sensors or controllers with sensing and monitoring capabilities, as well as mobile communication, intelligent analysis and other technologies into all aspects of the industrial production process. Significantly improve manufacturing efficiency, improve product quality, reduce product cost and resource consumption, and ultimately realize the promotion of traditional industries to a new stage of intelligence.

According to relevant data, by 2025, the number of connections with the global Industrial Internet of Things will reach 13.8 billion, of which the number of connections in Greater China will reach 4.1 billion, accounting for about 1/3 of the global market. According to a survey by the Ministry of Information Technology, the annual revenue growth rate of China's industrial IoT market is about 25%, and it will exceed 500 billion yuan in 2022. This indicates that the IIoT is ushering in a period of rapid development.

The Industrial Internet of Things, thanks to its real-time sensing and monitoring during operations, enables businesses to make more informed optimization decisions. These connections can also increase efficiency by establishing remote access. Devices with sensors for the IIoT can communicate with each other, making automated systems more flexible. IIoT devices can also reduce energy consumption by adjusting to use only relevant functions. Here are the top 10 benefits of IIoT deployments:

1. Production system perception and monitoring:

At the heart of an IIoT solution is continuous communication between systems and machines to ensure optimized throughput and real-time identification of machine defects.

2. Manufacturing process optimization:

Machines and equipment equipped with sensors and managed using IIoT systems can monitor conditions, equipment and workflows such as machine performance, assembly line management, supply chain optimization, workforce safety or quality assurance processes for optimization.

3. Predictive maintenance:

Over 75% of equipment and system failures occur without notice. With IIoT, preventive maintenance combines analytics to predict machine failure.

4. Optimize the quality:

It solves problems on the production line instantly, reducing downtime, lost productivity and product defects, and IIoT devices are programmed to monitor material quality, analyze equipment performance in real-time, and measure and measure finished products.

5. Inventory and Supply Chain Management:

Data, analytics, insights and contextual intelligence enable inventory systems to operate seamlessly to more accurately estimate available materials, work-in-progress and new material ETAs, which can help optimize supply chains and cut costs.

6. Customer service level and satisfaction:

Sensor-equipped production systems and inventories can enable customers to see the progress of their orders in near real-time. Sensors provide insights into customer usage that can help manufacturers improve functionality, alert customers to issues and bottlenecks, and differentiate themselves from the competition.

7. Worker Safety and Health:

Smart wearables allow managers to monitor the health and safety of production workers by tracking the history of illnesses and injuries, absences, mistakes, machinery or vehicle accidents, or life-threatening events such as gas leaks.

8. Energy Management and Sustainability

Industrial manufacturing consumes 54% of the world's electricity. Manufacturers using the IIoT can significantly improve energy efficiency by optimizing energy consumption.

9. Service provision and coordination

Industrial IoT-enabled field service delivery is a value-based approach based on factors provided, such as the timing of a given service activity, context, and technician involvement.

10. Service Contract Compliance and Performance

IIoT enables real-time data visibility, so both original equipment manufacturers (OEMs) and users can be aware of risks and issues as they arise.

Despite the above advantages, industrial IoT applications also face enormous challenges:

1. Lack of standardization: There are many different formats and technologies that can meet the different requirements of machine-to-machine communication between connected devices, such as Sigfox and Zigee technologies, for an IIoT environment, they must be interoperable.

2. Compatibility with legacy device technologies: Many older devices were not designed to provide the relevant specific formats for modern technologies, so decades-old factory equipment may require some retrofitting to communicate with complex IIoT devices.

3. Security issues: any device is controlled by network communication, it is easy to be hacked in the face of the Internet, IIoT has no way to avoid this, many low-cost devices, such as remote cameras, routers and even DVRs have limited security functions (including hard encoded default password and telnet access), or never update the patch. Once compromised, they can cause problems such as DDos attacks and malware distribution.

As the IIoT spreads, these technologies will become more accessible and affordable, and the benefits can offset the initial cost. Tighter cybersecurity standards can address growing cyber threats. While the IIoT is still relatively new and faces some challenges, the technology can give those who successfully implement it a competitive advantage. Believe in IIoT (Industrial Internet of Things), this technology will bring us more innovations and more surprises!