Wind power is a renewable and sustainable source of clean energy. Energy projects that have been vigorously promoted and developed by the country have important economic value. At present, the proportion of wind power generation in domestic installed power generation capacity is 4%, which shows that the potential of wind power generation in the future is huge and there is room for development.

The wind control system is mainly divided into 3 major components:

1. The wind farm unit control unit, which realizes the parameters monitoring, power generation control and equipment protection of the unit is the core part of the fan control;

2. High-speed ring-shaped redundant communication unit is a highway in which the on-site generator set and the remote operation center HMI interact in real time.

3. The upper computer operation center station has complete monitoring of unit status, parameter alarms, real-time / historical data recording and display functions, and real-time operation of the organic group in wind locations.

Introduction of the solution

Ebyte focuses on the wireless communication industry. After years of industrial field data communication practices, it can provide a variety of wind farm ring redundant communication solutions for implementation. There are wireless lora and 4G communication solutions.

Wireless lora communication solution

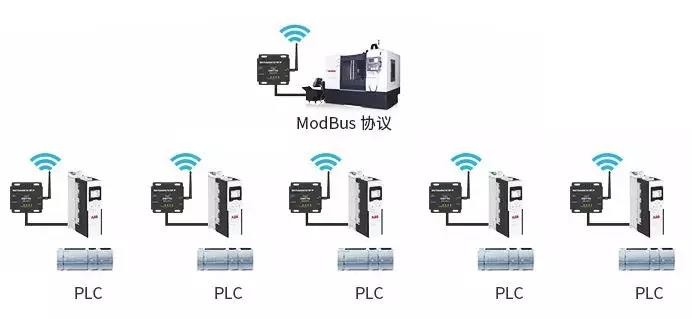

The fan unit adopts Bachmann PLC or domestic fan PLC to control the parameters of the wind farm unit. The EBYTE E90-DTU (433C30) uses RS485 to communicate with the PLC control unit, and the E90-DTU (433C30E) corresponding to lora wireless point-to-point communication Ethernet access Ethernet switch or control station gateway. The host computer HMI platform is connected to the network and monitors the fan operation through the modbus protocol.

4G base station communication scheme

The fan unit also uses Bachmann PLC or domestic fan PLC to control the parameters of the wind farm unit. The RS485 connection E840-DTU (4G-02E) is used to connect the PLC control unit using serial communication. The real-time data of the fan is uploaded to the base station network of the telecommunications operator. The project system cloud platform, the remote operation center station host computer HMI network is connected to the cloud platform, and the fan operation is monitored through the modbus protocol.

The wireless lora communication solution is suitable for remote areas where there is no coverage of the telecommunications operator's base station network signal. The wireless solution saves long-distance wiring costs. If the wind farm area is covered by 4G network signals, it is recommended to use the 4G communication DTU E840-DTU (4G-02E) to meet the more demanding real-time monitoring requirements.

- Several communication protocols commonly used in single-chip microcomputer

- What does Wi-Fi 7 mean?

- Detailed explanation of the principle of transistor logic circuit

- Application of Internet of Things wireless communication radio frequency module in smart lighting

- Modbus Protocol PLC Wireless Communication Monitoring Wind Power Generation