In daily enterprise production, traditional serial devices such as RS485, RS232, RS422 and other interfaces have been widely used, but in actual automated production, it is often necessary to realize data communication of hundreds of meters or even thousands of meters. To realize remote monitoring, it is necessary to Will face these problems:

(1) The communication distance is too far

(2) Scattered data points

(3) The wiring in the networking is too complicated

(4) Wiring is highly restrictive

(5) The problem of line damage often occurs

(6) Difficult to find and repair

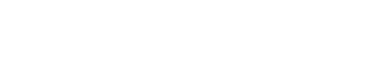

When the Internet of Things technology came out, this problem was solved by the RS485 to LoRaWAN data collector. Using LoRa wireless technology and LoRaWAN gateway, the complicated wiring was successfully canceled, and wireless communication replaced wired communication.

Why many applications of IoT are not commonly using LoRaWan network protocol?

Related to LoRaWAN Article :

Teach you how to build a LoRaWAN automatic acquisition system

The difference between LoRa wireless transmission technology and LoRaWAN wireless module

How does the network architecture of the standard LoRaWAN Gateway Protocol work?

Advantages of RS485 to LoRaWAN data collector:

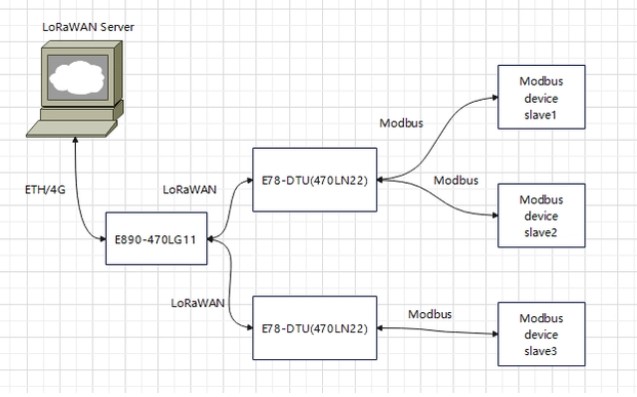

The RS485-to-LoRaWAN data collector is a data collector whose uplink wireless interface adopts the standard LoRaWAN protocol and the downlink interface adopts the RS485 interface. It can transparently transmit the ModBus protocol to the server through the LoRaWAN wireless network to realize the wireless transmission of industrial field control signals. .

The E78-DTU (470LN22) developed by Ebyte is a data collector suitable for industrial environments. Its uplink wireless interface adopts the standard LoRaWAN protocol, supports the file communication frequency band in the CN470 area, and is equipped with one RS485 serial port. Effective communication coverage can also be provided in the field. It has the following characteristics:

(1) Support LoRaWAN 1.0.2/1.0.3 protocol

(2) Two-way transparent transmission from RS485 to LoRaWAN

(3) LoRaWAN CLASS A and CLASS C modes

(4) LoRaWAN OTAA and ABP two network access methods

(5) ModBus polling, supports up to 64 polling commands

(6) Active query function, which can send read commands from the remote server to read RS485 bus data

The command storage function of the product is a worthwhile function. When the command forwarded by the LoRaWAN gateway is not received, it can also actively poll the devices on the RS485 bus to achieve the purpose of regularly reporting the data of the RS485 bus device, thereby reducing the number of LoRaWAN gateways. workload, reduce the number of instructions issued, reduce the bandwidth used by the network, and avoid network congestion.

In a typical LoRaWAN networking case, some ModBus slave devices are arranged on the industrial site. Since the devices are scattered, if we want to transmit data to the server with less wiring, we need a device that can read ModBus The other end can also be uploaded to the intermediate device of the LoRaWAN gateway to replace the direct communication between the server and the device, so we can choose E78-DTU (470LN22) as an intermediate device to cooperate with the LoRaWAN gateway device to transmit the collected data to the server. Of course, the E78-DTU (470LN22) has the function of two-way transparent transmission, and the cloud server can also actively issue collection commands to read ModBus slave device data.

In industrial application scenarios, the introduction of RS485 to LoRaWAN data collectors in networking solutions can bring the following advantages:

(1) Wireless networking, reducing wiring costs;

(2) Even in the complex environment of industrial sites, LoRa signals can provide strong coverage capabilities;

(3) It is convenient and fast to build a wireless chemical industry on-site control system;

(4) Realize low power consumption networking.